Fraccaroli & Balzan filterpressi automaatika

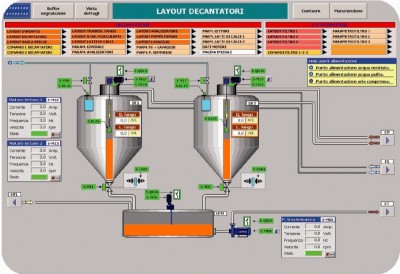

With the PLC, it is possible to control, see and change the working parameters of the plant.

Automatic flocculant dosig

In the flocculant station a solution of water and flocculant is prepared, and is subsequently injected into the pipe feeding the decanter. The flocculant acts on the solid particles increasing their settling speed.

Automatic flocculant optimization system

Automatic flocculant optimization system

The plants can be equipped with a device for the automatic control and dosage of the flocculant which detects and controls the presence of mud in the water through the examination of a sample of decanting water. This solution allow average flocculant reduce 25% giving fast payback time.

Tele assistance.

The filterpress parameters are transmitted from the PLC in the electric panel board to

Fraccaroli e Balzan S.p.A. offices through modem connection.

Automatic washing system for the filter screen

Automatic washing system for the filter screen

A sliding trolley positions the device for the automatic programmed washing of the filter screens in the spaces between two adjacent plates. The screens are washed one by one by a high pressure water jet.

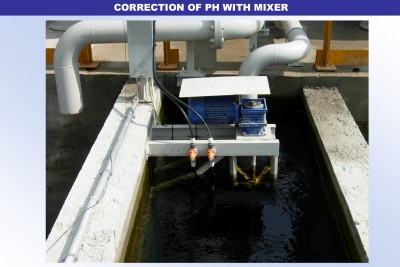

System for pH correction

Depending of process needs pH value is corrected before filtering or waste water disposal.

Full automatic robot system

Fraccaroli & Balzan is first filterpress manufacturer to use robotic solutions.

Robot open-close plates, shake plates and wash plates. This solution save a lot time in filterpress operation giving possibility to reduce filterpress overall dimension giving considerable saving to projects.